What is the difference between square and rectangle steel tube?

2024-10-25

What is the length of RHS and SHS steel?

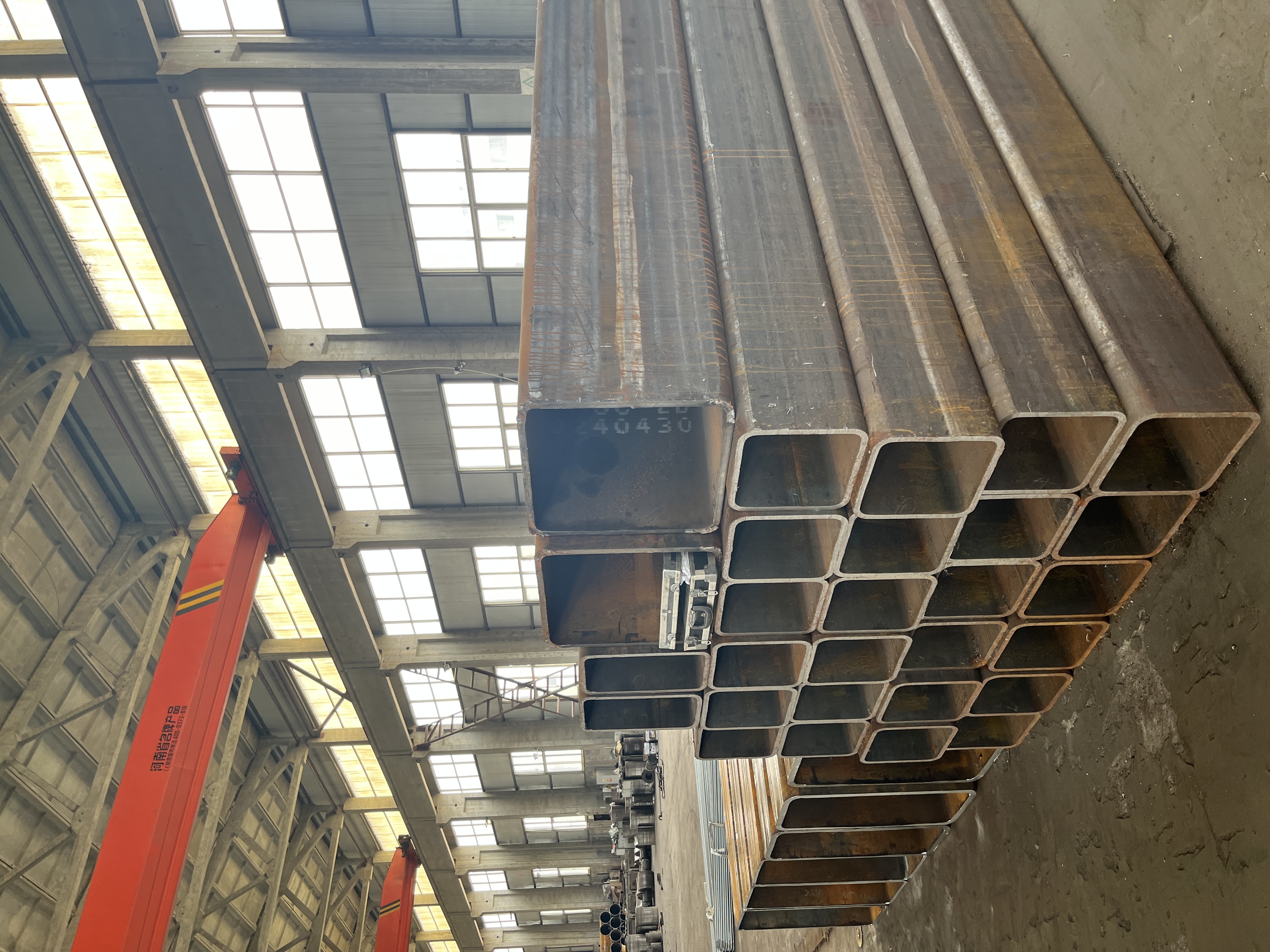

Square hollow section steel (SHS) has various lengths to choose from. SHS also offers standard sizes for square sizes ranging from 100 * 100mm to 1200 * 1200mm and rectangular sizes ranging from 100 * 150mm to 1200mm.

The length range of SHS is 6.0m-12m, and it is not limited to these lengths. The thickness range is 4.0mm to 50.0mm.

As mentioned above, painted rectangular hollow section steel (RHS) can provide many different lengths. If you need the length of painted structural pipes not listed in our product list, we provide fixed length cutting services. We also offer many other processing services that can be customized according to your specific requirements

What are the uses of RHS and SHS steel?

Haoxintai Steel Center distributes and supplies RHS and SHS structural steel pipes worldwide, widely used in various environments and industries. The environment and industries include engineering construction, residential construction, commercial construction, mining, logistics, manufacturing, and agriculture. The commonly used applications of SHS and RHS steel include glass curtain walls and welded steel frames for sports venues. Rectangular and square hollow steel sections are also commonly used for beams in building applications.

Key words:

RELATED INFORMATION

Advantages And Disadvantages Of Carbon Steel Pipes

2024-10-10

Commonly used pipe-making process for large-caliber steel pipes

2024-05-22